Our modular skidded systems can be configured to our internal standards or customized to meet your company, industry or project specific requirements.

CIP/SIP SKIDS

Clean-in-place (CIP) or sanitize-in-place (SIP) is a procedure by which process lines, tanks and equipment are sanitized without any disassembly. Sterling will specify, design and fabricate CIP/SIP systems tailored to your needs, whether it be manual or fully automated. We will conduct a thorough evaluation of your current process system prior to the design of your new system. We understand the necessity of cleaning individual systems or entire plants in a timely manner, while balancing the costs associated with heated water, cleaners and waste water treatment.

MIXING AND BLENDING SKIDS

Mixing and blending tanks are commonplace in a variety of industries. Typically, these tanks are one of the first few steps in production to mix raw materials (liquid or solid) and transfer them downstream to continue the production process. These raw materials are controlled as they enter the tank (weight, flowrate or level), blended by some form of agitation, potentially heated or cooled, and then metered as the mixture is pumped out of the vessel. Automation of the system allows for multiple recipes or batches to be processed consistently on the same system. Sterling has extensive experience in packaging the vessels, equipment, controls and piping into a skidded module to simplify installation, integration and minimize the interruption of existing production. Customers have the ability to perform Factory Acceptance Testing (FAT) at our facilities, offering familiarity with the system function and peace of mind prior to shipping the project.

HOT WATER SETS

Hot water sets (HWS) are used across multiple industries to provide controlled water temperature to various process requirements like ingredient hot water, tank jacket heating and cleaning/sanitization. Sterling has experience designing HWS that use various types of heating equipment, such as direct steam injectors (DSI), plate and frame heat exchangers and shell and tube heat exchangers. Systems can range from simple manually controlled skids to automated systems with HMI integration.

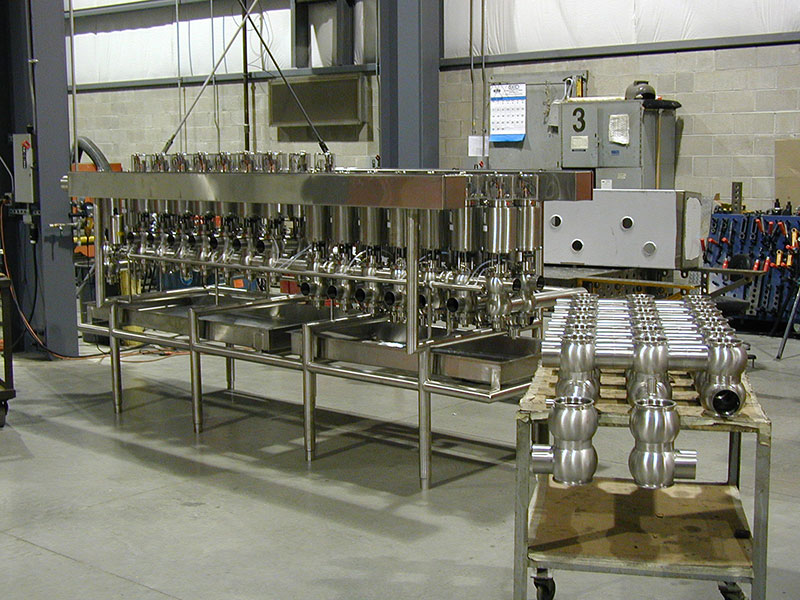

VALVE CLUSTERS

Valve clusters are a means of distribution and flow control, allowing for product and CIP solution to be efficiently transferred between holding tanks, mixing tanks, fillers and other process equipment with limited-to-no employee interaction. Sterling will design a valve cluster to meet customer and process requirements, delivering an effective solution using minimal components and ensuring cleanability and drainability. The valve matrices are fabricated using orbital welding to minimize valve body stress and borescope inspected to ensure quality. The valve cluster is supplied fully assembled, wired and tested, mounted to a skid frame, and ready for installation.

COP TANKS

Clean-Out-of-Place (COP) is a procedure by which process line components, tank components and equipment are sanitized by disassembling. When process or budget constraints necessitate manual cleaning, Sterling will specify, design and fabricate COP tank systems tailored to your needs. A thorough evaluation of your process system will be conducted prior to the design of your system. We understand the necessity of cleaning individual components in a safe and timely manner, while balancing the costs associated with heated water, cleaners and water treatment.

Request a Quote.

We would love the opportunity to connect, learn more about you and discuss your needs. If you require engineering, fabrication or installation services, we encourage you to consider Sterling for your next project. Please fill out your contact information and a representative will contact you within 24 hours.