versatile, effective solution for system cleaning

We understand the necessity of cleaning individual systems or entire plants in a timely manner, while balancing the costs associated with heated water, cleaners, and wastewater treatment. Sterling’s CIP systems automate your cleaning process to efficiently clean and disinfect your enclosed process lines, tanks, and equipment without the need to disassemble.

CIP SYSTEMS TAILORED TO YOUR SPECIFIC NEEDS

If one of our standard offerings does not meet your specific needs, we will develop a system purpose-built to your requirements. Sterling will conduct a thorough evaluation of your current process system and will then specify, design, and fabricate CIP/SIP systems tailored to your needs, whether it be manual or fully automated.

Sterling’s systems work in a variety of applications and are easy-to-move to on-demand locations including:

- Electric Heater (2°F rise/minute)

- Steam Heater (20°F rise/minute)

- CIP Supply flow metering for automated dynamic flow rate

- Automated Chemical Injection

- USB Connection for simplified process data export

ADVANTAGES OF A CIP SYSTEM

- MINIMIZE MISTAKES

Reduce the chance of human error, which can contribute to an unsafe product. - KEEP EMPLOYEES SAFE

Avoid chemical exposure by containing cleaning solutions within the system. - INCREASE PRODUCTION TIME

Save time from not having to manually clean and use that time toward product production. - ENSURE PRODUCT QUALITY

Ensure quality and brand confidence with reliable and repeatable cleaning for sustainable product quality and consistency and less contamination, which means fewer product recalls. - UTILITY SAVINGS

Reduce water and energy usage through repeatable cycle control. - DIGITAL DOCUMENTATION

Optional Control Reporting Packaging provides Digital Documentation eliminating the needs for paper records.

the CUSTOM-BUILT Sterling CIP systems also come with various options and add-ons. COMPLETE THE FORM BELOW To request a quote for your SPECIFIC NEEDS.

gain confidence in your cip cleaning program

Sterling’s Portable CIP Cart is designed to meet FDA/CFR/3A requirements info and is designed to fit through a standard 36” x 80″-man door. Sterling’s Portable CIP Cart features all the necessary equipment and instrumentation to give you confidence in your CIP cleaning program, including:

- Industry leading Alfa Laval stem valves, pumps & strainers

- 8 Port Solenoid Manifold with external air connections to isolate air from electrical components, Ethernet

- Electronic Circuit Breakers for 24VDC components

- Eliminate the need to replace fuses with the Molded Case Circuit Breaker with Rotary Enclosure Disconnect

- IP69k IOLink Master Module for Skid Mounted Hardware allows for automatic instrument replacement, Ethernet connectivity

- Powerflex 525 Series VFD with built-in Safe Torque Off, Ethernet connectivity & speed can be set manually from 0-100%. Optional flow meter can allow for automatic flow rate control

- Robust sensor technology from IFM & Anderson-Negele

- 480VAC to 24VDC Power Supply allows for one power connection

- Stainless Steel Nema 4X enclosure

- 7” Widescreen PanelView 5310 Graphic Terminal, Ethernet connectivity with up to 1 year of historical process data saved to internal SD card

- Guardmaster Safety Relay with Enclosure mounted E-Stop, which features twist to release and self-monitoring contacts

- Compact Logix 5069 Programmable Logic Controller, Dual Ethernet ports for Plant & Local connections – plant port IP address setup is included

- Use to passivate new & existing lines and tanks with applicable chemicals

Need something bigger? Sterling offers 2 to 6 tank CIP systems to meet larger capacity cleaning requirements.

utility requirements

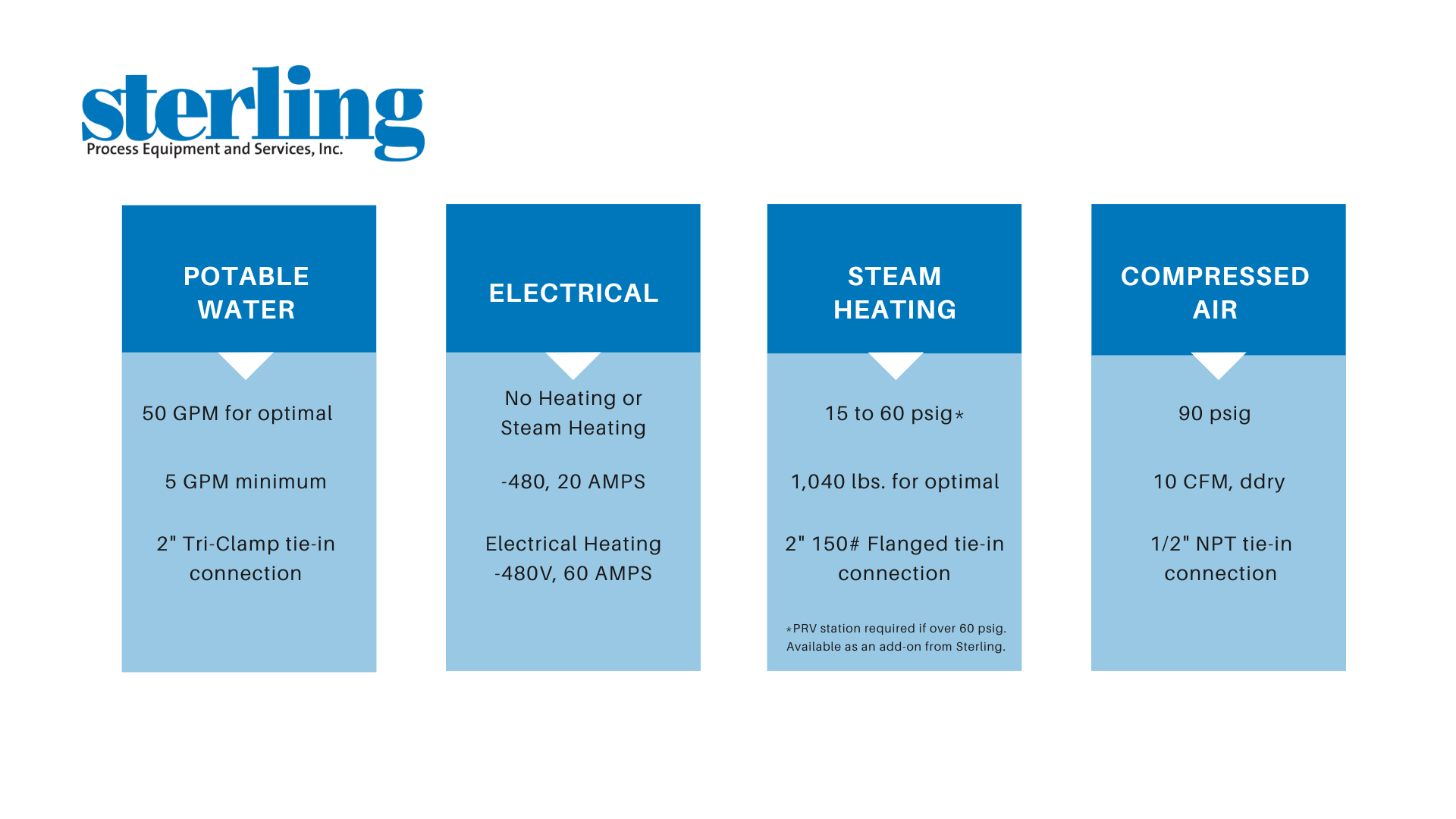

There are specific utility requirements that come with any Sterling CIP system including: