Sterling has established a strong niche in the market by specializing in stainless steel fabrication.

We have dedicated our 35,000 square foot facility to the specific requirements of stainless steel and non-ferrous alloy fabrication. Sterling utilizes the latest technology in forming, welding, and polishing. We have trained artisans who know the intimate details of fabricating, welding and polishing stainless steel, as well as other nickel alloys. Their attention to detail is an integral part of every project that passes through our quality control inspections.

CAPABILITIES

facility specification / shop equipment

facility

- 35,000 Sq. Ft. fabricating facility

- Five and ten ton overhead cranes

- Two 50 X 150 bays for large projects with a segregated metal finishing area

water jet cutting features

- Close tolerances, less secondary operations

- Cut 12″ thick stainless steel, aluminum, copper

- No HAZ (heat affected zone)

- Software for most ACAD, DXF, or scanned files

- Table size 72″ X axis 156″ Y axis

cutting capabilities

- Manual Plasma up to 1″ plate

- Vertical Band Saw 16″ x 22″

shearing capabilities

- Maximum capacity 1/4″ stainless steel 13’4″ long

punching capabilities

- CNC Gauging,

- Repeatability tolerance: 0.005″

- Weight capacity: 30 Ton

- Work envelope: 120″ X axis, 30″ Y axis, tooling up to 5″

machining capabilities

- Drill Presses

- Milling Machines

- Tapping Machines

- Lathe Turning

forming capabilities

- 230 ton capacity, 14′ long, computer gauging, up to 1/4″ stainless steel plate 12′ long

- 55 ton capacity, 6′ long, computer gauging

- Pipe and tube bending

rolling capabilities

- Three sets of rolls

- Up to 1/4″ thick 72″ wide

welding capabilities

- Automatic orbital tube and pipe welding

- GTAW/GTAW-P

- GMAW/GMAW-P

- SMAW

- FCMA

- Precision modular fixturing systems for welding, machining and positioning

welding inspection capabilities

- Fiber Optic Borescope with recording capabilities

- Magnaflux

- Die Penetrant

- On staff CWI’s and third party NDT professionals

polishing capabilities

- Custom polish bars, plate, round and square tube to 3-a sanitary or other specifications

- Custom polish random lengths of flats, rounds and rectangular stock to any finish specified

- Tank and vessel polishing to 3-a sanitary specifications

- Centerless grinders

- Flexible shaft grinder machine, variable speed

Bead Blasting CapaBilities

- Self-contained booth dedicated to non-ferrous metals

- Media: glass bead, sand (when applicable)

- 350 Sq. Ft.

- 16′ wide 21′ long 12′ tall

certifications

welding

Numerous welding process and inspections are available.

Welding processes include GTAW, GTAW-P, GMAW, GMAW-P, SMAW and FCMA. We have numerous welding qualifications per ASME Section IX, as well as AWS D1.1, D1.2 and D1.6. Orbital Welding technology can used on tube and thin wall pipe fabrications. Complete welding documentation and inspection is available.

contract manufacturing

Sterling’s contract manufacturing services provide parts and weldments on behalf of the customer. The design and branding remains the property of the OEM, while Sterling offers design and prototyping to final production, assembly, and inspection of products. Other manufacturing services may include sheet metal fabrication, machining and turning, welding, finishing, passivating, etching and bagging.

Sterling currently handles multiple designs for numerous customers across a variety of industries. If you have a product, component or system in need of manufacturing, Sterling is happy to discuss new opportunities with perspective partners.

water jet cutting features

capabilities

- Close tolerances, less secondary operations

- Cut 12″ thick stainless steel, aluminum, copper

- No HAZ (heat affected zone)

- Software for most ACAD, DXF, or scanned files

- Table size 72″ X axis 156″ Y axis

- Able to cut a wide variety of materials, including but not limited to: metals, woods, composites, plastic and foam

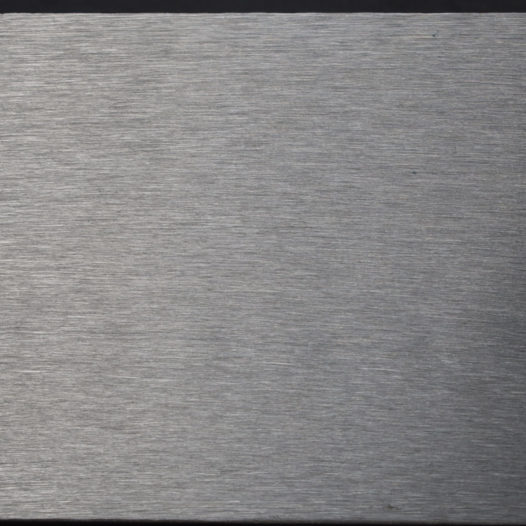

finishing

polishing

We have designed and built custom equipment for polishing applications, which gives us a competitive advantage. We can custom polish lengths of flats, rounds and rectangular stock to any finish specified.

pickling/passivation

Specialized tanks and troughs allow us to pickle and passivate a variety of shapes and sizes to ensure the highest levels of corrosion resistance.

chemical etching

Using any stencil design, Sterling is able to chemically etch logos, text and more onto stainless steel.

Glass Bead Blasting

If a uniform, unique finish is desired on your weldment then glass bead is an appropriate option. Using any stencil design, Sterling is able to blast logos, text and more onto stainless steel.

Our bead blasting capabilities include:

- Self-contained booth dedicated to non-ferrous metals

- Media: glass bead, sand (when applicable)

- 350 sq. ft.

- 16′ wide 21′ long 14′ tall

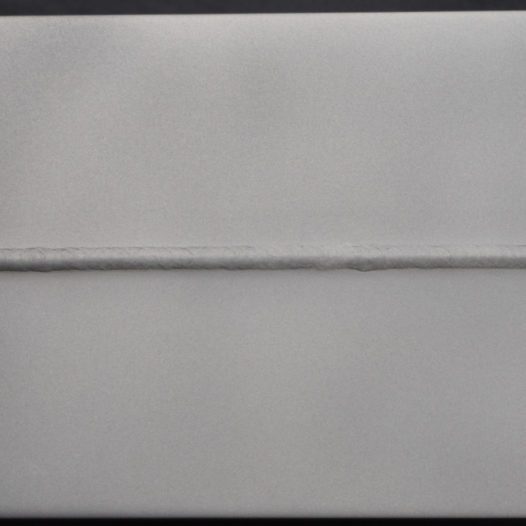

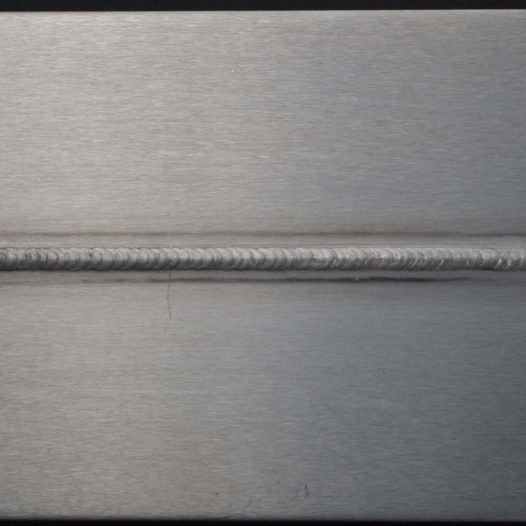

standard weld finishing types

As Welded

bb-bead blast

- Glass Bead, Small or Large Booth

- Completed part or sub assembly receives a glass bead finish

bu-buff

- Weld is buffed with one of several methods to achieve desired finish

ep-electro polishing

- Weld is ground and polished to blend with surrounding base grain to a final 240+ grit finish

- Then buffed to a mirror finish

- The part is then electro-polished

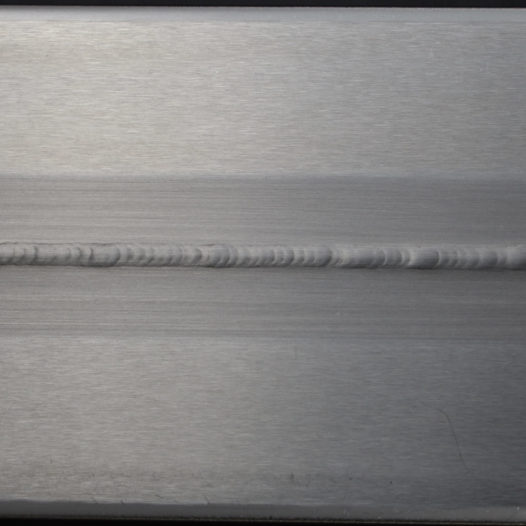

gm-grind medium

- Weld is ground with the base grain to a final 80 – 120 grit finish

gr-grind rough

- Weld is ground with the base grain to a final 60 grit finish

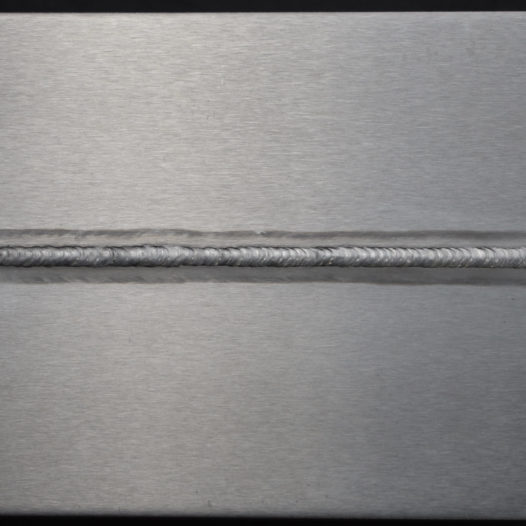

pb-a polish & blend aesthetic

- Weld is ground and polished to blend with surrounding base grain to a final 80 – 120 grit finish

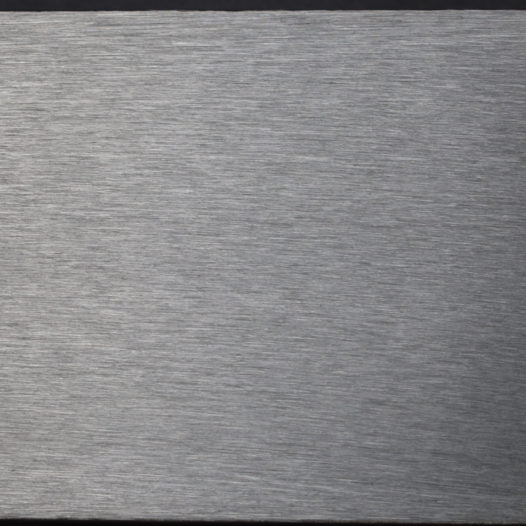

pb-bpe polish & blend biopharm

- Weld is ground and polished to blend with surrounding base grain to a final 240 grit or 20 Ra finish

pb-m polish & blend mirror

- Weld is ground and polished to blend with surrounding base grain to a final 240+ grit finish then buffed to a mirror finish

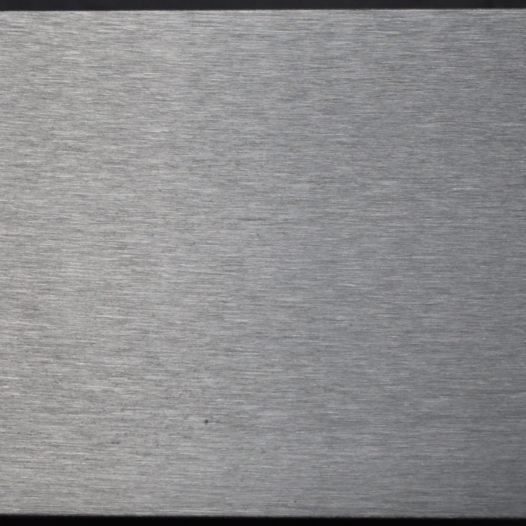

pb-s polish & blend sanitary

- Weld is ground and polished to blend with surrounding base grain to a final 180 grit or 32 Ra finish

pk-pickle

- Part or weldment is chemically treated to remove oxides, iron contamination and weld discoloration

sb-stripe buff

- Weld is buffed with one of several methods with a hard line following the base grain direction to achieve the desired finish

sk-electro-clean

- Part or weldment is electro-chemically treated to remove oxides, iron contamination and weld discoloration

sp-a stripe polish aesthetic

- Weld is ground and polished with a hard line following the base grain direction to a final 120 grit or 52 Ra finish

sp-bpe stripe polish biopharm

- Weld is ground and polished with a hard line following the base grain direction to a final 240 grit or 20 Ra finish

sp-s stripe polish sanitary

- Weld is ground and polished with a hard line following the base grain direction to a final 180 grit or 32 Ra finish

Contact us.

We would love the opportunity to connect, learn more about you and discuss your needs. If you require engineering, fabrication or installation services, we encourage you to consider Sterling for your next project. Please fill out your contact information and a representative will contact you within 24 hours.